Process

Mirror polished stainless steel sculpture is commonly used in modern public art because of its stunning finishing and beautiful artistic appearance. However, we also well known that it is not easy to fabricate perfect mirror polished stainless steel artworks.

Here. we’d like to introduce the technique and workflow Trevi Art Sculpture employs to create art fabrication stainless steel artworks. This is a outdoor large polished stainless steel sculpture made for clients from Saudi Arabia.The size of this stainless steel sculpture is about 6m height, 2.6m width.

Here is a brief description on how our factory made this outdoor large polished stainless steel sculpture.

1. Drawing or sketches picture of the stainless steel sculpture

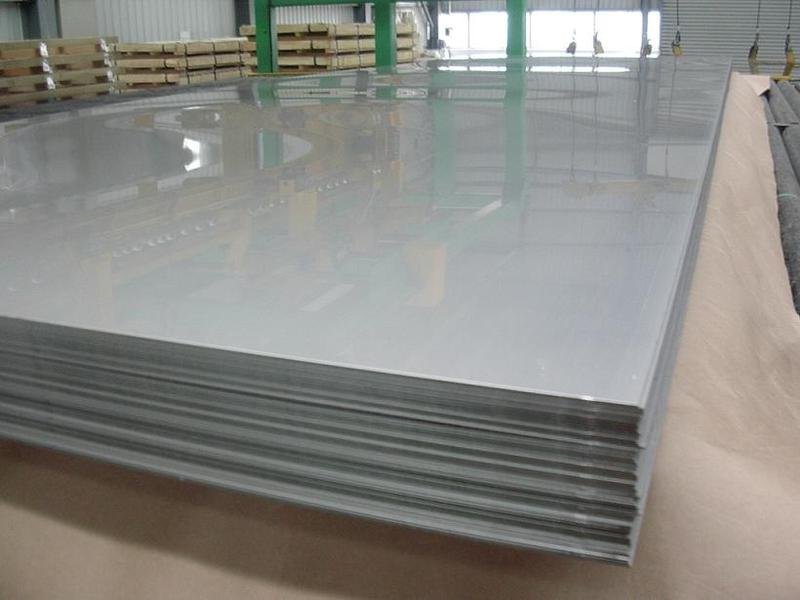

2. Engineering and Preping stainless steel sheet.

High quality stainless steel is the foundation to create beautiful works. We use the marine grade stainless steel sheet 316, which features superior corrosion resistance performance and high strength. It is crucial to make sure that the stainless steel sculptures will never get corrosion placed outdoors, even in warm and high humidity environment. Compared with stainless steel Grade 201 and 304, stainless steel 316 works much more better on build quality.

The armature and the base of the sculptures is 16 MM thick,which is extremely strong for the structure. It can even stands a couple adults climbing on the sculpture.

3. Cutting and bending the stainless steel sheeting according to design.

Cutting and bending the stainless steel sheeting according to design.We use high precision water jet cutter or plasma cutter to cut stainless steel sheet into the shape we wanted.

4. Welding the Pieces of Stainless Steel Sculpture Together. All joints are full welded to maximize strength

All joints are full welded to maximize strength. We use TIG and MIG for welding. The welding rods have to be exactly the same as the stainless steel sheet. Otherwise there will be imperfection on the finished works.

5. Polishing the Surface of Modern Stainless Steel Sculpture

Polishing is a dirty job, involving many steps, which have to be performed in correct order and in right technique.

These are material commonly used for polishing of Stainless Steel Sculpture: polishing wheel, cotton wheel, non-woven wheel and polishing paste. The hard and tough polishing wheel is used in first stage and then softer cotton wheel. Polishgin paste of different colors are also used in different stage.

6. Trial installation large polished Stainless Steel Sculpture at factory

Every large polished stainless steel sculpture we would have a trial installation in our factory before shipping, and show the video and picture to clients to confirm.

Feel free to let us know if you have any technical question on how to fabricate stainless steel sculptures or you need a quote for your own project. We’ve been to many countries to install the large stainless steel sculptures, so our skilled and professional team can install the stainless steel sculpture safely.

7. Packaging of Stainless Steel Sculpture

8. Shipping of Stainless Steel Sculpture